With the manufacturing suite of products from Dynamic Megabytes, customers can achieve their goals by defining their own requirements and executing them with customized software tailored to their specific business for better efficiency and improved competitiveness. In addition, customers benefit from the expertise of software programmers who are knowledgeable of the manufacturing industry. This expertise began almost 27 years ago with founder and president Ivan Vazan.

In 1989, which was still in the golden era of DOS operating language, Vazan finished his university education in the former Czechoslovakia, arrived in Canada, and co-wrote custom MRP (material requirements planning) software for a manufacturing firm. Two years later, Dynamic Megabytes, headquartered in Cambridge, Ontario, was founded. Vazan was able to use his extensive manufacturing experience to develop a comprehensive production-shop control software package.

In 1989, which was still in the golden era of DOS operating language, Vazan finished his university education in the former Czechoslovakia, arrived in Canada, and co-wrote custom MRP (material requirements planning) software for a manufacturing firm. Two years later, Dynamic Megabytes, headquartered in Cambridge, Ontario, was founded. Vazan was able to use his extensive manufacturing experience to develop a comprehensive production-shop control software package.

In 1995, the company grew and software expanded to tailor to the gear manufacturing industry. Software was also developed with time and attendance modules integrated with the main Canadian and U.S. payroll packages. In the late 1990s, a generic job-shop manufacturing module was developed, as well as a repetitive automotive production manufacturing module. Dynamic Megabytes became incorporated in 1998, and in the early 2000s, its software was completely re-written for Windows. Since then, the company’s software has been maintained and upgraded to utilize features and functionality for all versions of Windows, including Windows 10.

The software from Dynamic Megabytes is written by programmers with an understanding of the manufacturing industry process and is paired with a considerable amount of end-user input. The final result is a simple, user-friendly, yet intuitive and effective application.

The software from Dynamic Megabytes is written by programmers with an understanding of the manufacturing industry process and is paired with a considerable amount of end-user input. The final result is a simple, user-friendly, yet intuitive and effective application.

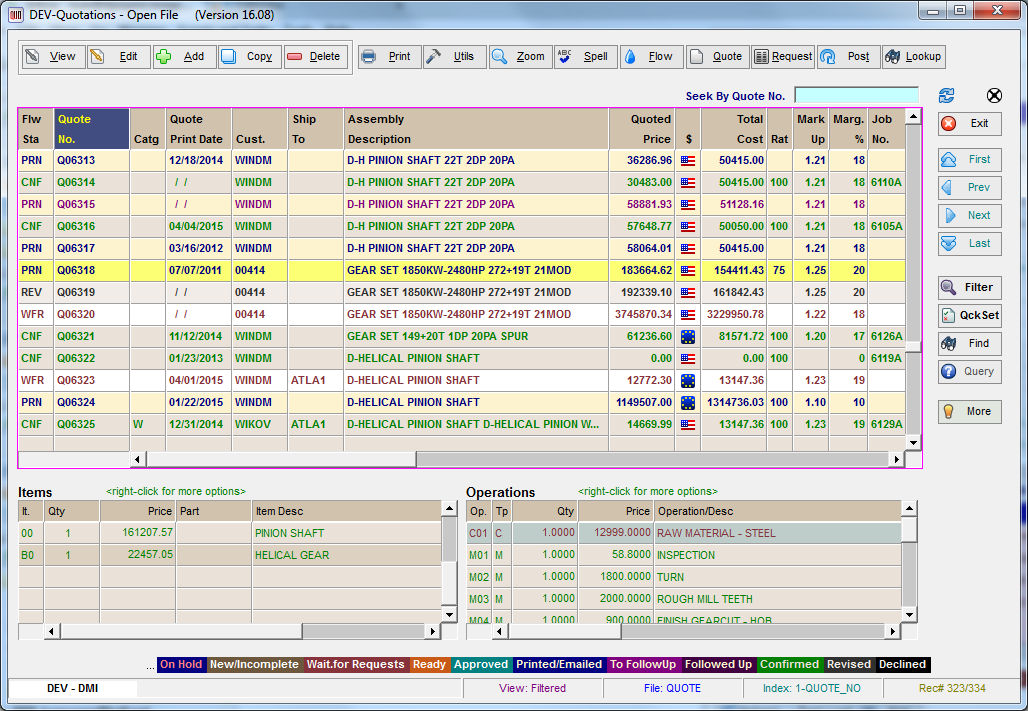

For an example of how Dynamic Megabytes helped a customer in the gear manufacturing industry, Vazan shares this testimonial. Prior to 1996, John Havlik Sr. (currently of Havlik Gear) was at the time working at Santasalo N/A, and he was using manual reference sheets and tables for quoting the jobs. It took a long time to calculate all aspects of each quote, such as weights, costs, markups, and pricing. Then Havlik began using the ManuX software from Dynamic Megabytes. Havlik’s input and intimate knowledge of the gear industry actually helped Dynamic Megabytes with the initial development of its gear manufacturing module. In turn, this collaboration has helped Havlik streamline his business, reduce costs, and increase revenues.

“After Havlik began using the software, he was on the phone with a potential customer, they finished talking about specs of the job, and then he surprised the prospect by saying, ‘Go check the fax machine; your quote is there.’ (This was the 1990s when fax machines were still being used),” said Vazan.

“After Havlik began using the software, he was on the phone with a potential customer, they finished talking about specs of the job, and then he surprised the prospect by saying, ‘Go check the fax machine; your quote is there.’ (This was the 1990s when fax machines were still being used),” said Vazan.

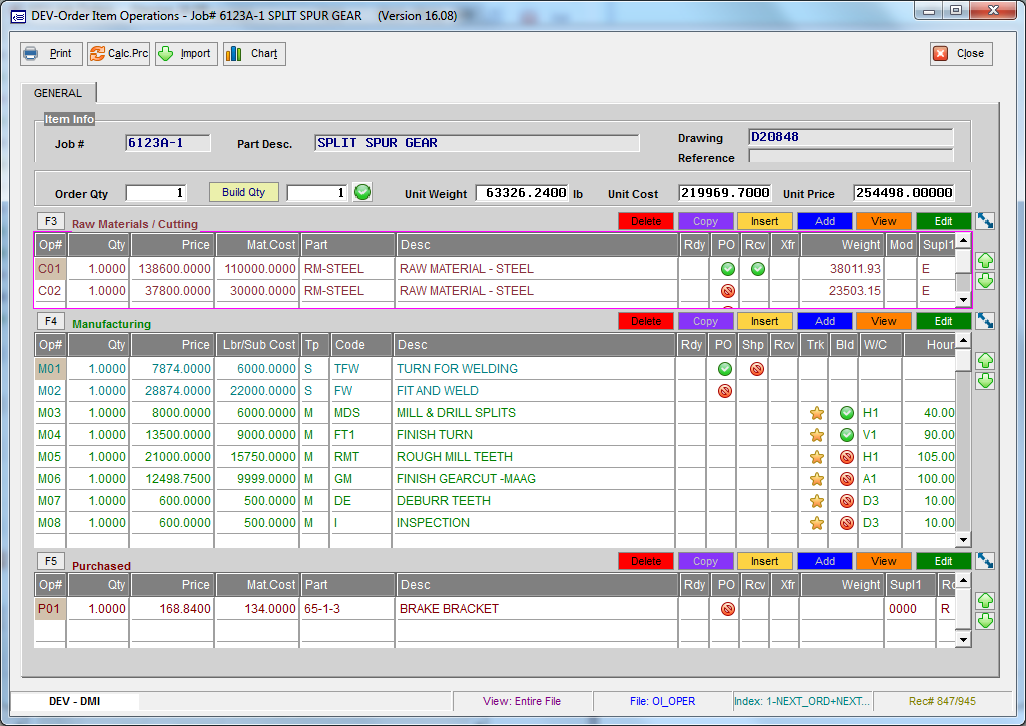

And that’s how fast a quote can be created using the software. Then, once Havlik receives acceptance of a quote, it is easily converted into an order. The software solution provides the visibility of the job from creation to final shipping — to view capacity and maximize machine loading and job scheduling, thus ensuring maximum throughput to deliver jobs on time.

Today, Havlik Gear and Santasalo are still both valued customers of Dynamic Megabytes.

Today, Havlik Gear and Santasalo are still both valued customers of Dynamic Megabytes.

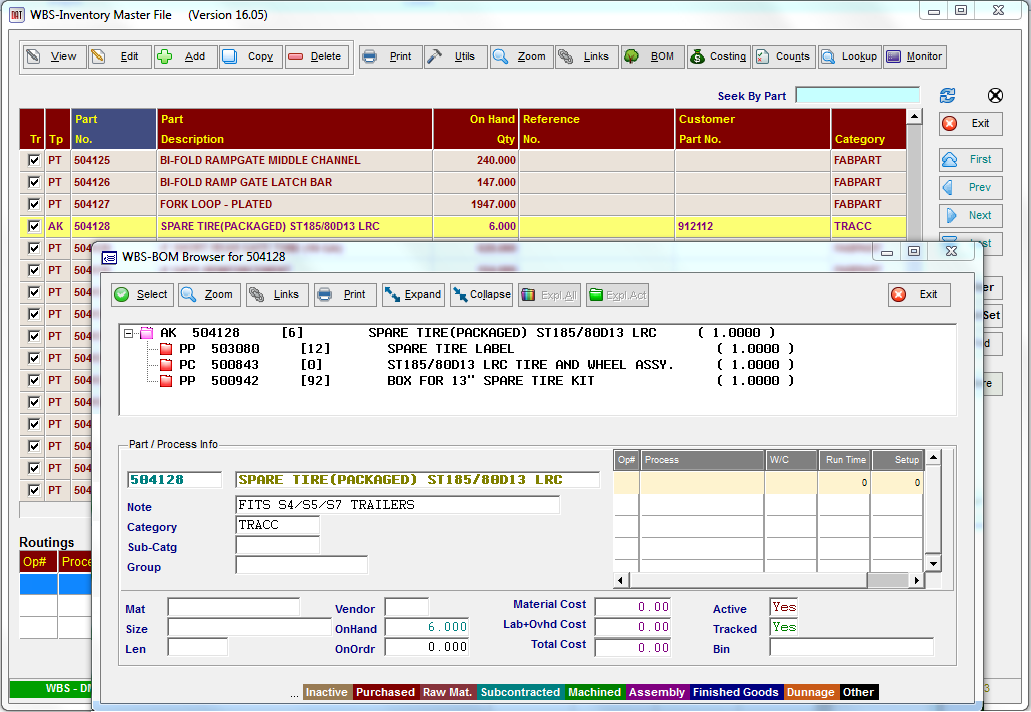

Dynamic Megabytes has also helped a high-volume full-service automotive components manufacturer improve its inventory accuracy and control, integrate with its customers through EDI (electronic data interchange), and conform to quality standards set by the automotive industry. The ManuX software solution helped the manufacturer remove buffer inventory and waste from production.

“Our customers are like family — we only take on a customer we know we can help, and then we ensure a smooth transition from existing software systems, or quite often, Excel spreadsheets,” said Vazan.

The ManuX software is a complete MRP and materials management software solution that is customized to the customer and can be suited to fit any budget — it’s ideal for small- to medium-sized businesses. The product is designed to support decision-making in a manufacturing company by communicating consistent priorities to those within an organization through its common databases, customizable inquiries, and full-featured reporting.

ManuX is a versatile application that can be used in repetitive production shops, job shops, or mixed environments. Implementation of ManuX can result in improvements in productivity and profit, including reduced purchasing costs, shortened delivery lead times, and reduced production interruptions caused by unavailable material.

ManuX is a versatile application that can be used in repetitive production shops, job shops, or mixed environments. Implementation of ManuX can result in improvements in productivity and profit, including reduced purchasing costs, shortened delivery lead times, and reduced production interruptions caused by unavailable material.

For production shops, the ManuX software features an inventory master browser and a multi-level bill of materials (BOM) where the user can enter the processes it takes to build a part, specify raw materials and components, and track costs for each level of the BOM. It can also generate a master production schedule, create purchase orders and invoices, and ship/receive to and from subcontractors.

For job shops, the ManuX software can develop quotes, create specialized processes with raw materials and specifications, and manage and track the progress of the manufacturing and purchasing.

All of the customizations are guaranteed by the company to work in the future releases, without having to pay again for subsequent versions. The system meets QS and ISO standards, and it is automotive MMOG compliant/approved and barcoding or scanning ready.

The benefits to choosing Dynamic Megabytes software include simple and fast implementation with low maintenance. Also, training and support is provided directly by the programming team with no offshore call centers.

The benefits to choosing Dynamic Megabytes software include simple and fast implementation with low maintenance. Also, training and support is provided directly by the programming team with no offshore call centers.

“Our services are direct, fast, and reliable with top-of-the-line knowledgeable help,” said Vazan. “We have a proven track record over the last 25 years, and customers see a return on investment within a few months.”

Vazan added that the company is continuously developing new features to adapt to a changing business and the technological environment with frequent releases for system enhancements.

FOR MORE INFORMATION, www.dynamicmegabytes.com