When it comes to material-associated gear manufacturing costs, machining and gear-tooth cutting costs stand out as primary contributors. The gear blank and tooth machining costs are further dependent upon the machine tool/machining methods used and the associated cutting insert/tool. The interaction between the tools and the base material determines the life or number of parts cut on each tool. For many machining operations, the advances in machine tool and insert/coating technology have greatly reduced the overall per-part machining costs regardless of the base material properties. However, there remain a few operations where the per-part cost can be quite high.

Historically, each alloy grade had associated with it an appropriate thermal treatment that would be applied to optimize the machining characteristics, as follows:

- Low carbon/alloy: Reduced cooling from hot working, normalize, and/or temper.

- Medium carbon/low alloy: Normalize and temper or fine pearlitic, lamellar anneal.

- Medium/high carbon/alloy: Coarse lamellar pearlitic or partial spheroidize anneal.

- High carbon: Fully spheroidize anneal.

However, the more robust machining operations have made these annealing cycles optional for many applications, and instead, the annealing costs might be weighed against the increased machining costs or subsequent heat treatments required to regain properties. As such, many applications are now machined in a semi-hard state, reducing the thermal treatment costs while maintaining the core or base properties required for the application.

The typical method to approach improving machinability of steel parts such as gears involves improvements in the machine tool arena of the operations including the machine tool itself, the cutting tools used for the operation, and perhaps the coolant type and flow. However, there are also opportunities to improve the machinability of gears through optimization of the metallurgical properties of the gear materials going into the machining operations. Historically, improvements in steel machinability had been accomplished by adding inclusions to aid in chip formation and improved tool wear; however, these additives are deleterious to the gear properties, and the improved property requirements for premium gears have reduced the acceptability of this approach. Alternatively, machining improvements can be accomplished through an alloy design or selection approach, a thermal treatment applied prior to the machining operations, or some combination of these.

One such operation that lends itself well to material optimization to reducing machining costs is broaching of gear teeth, and in particular internal helical ring gears. Broaching is a machining technique commonly used to cut gear teeth where the tooth profiles can be formed in a single machining operation with minimal overall time, making it ideal for cost-sensitive applications [1]. However, in order to accomplish the broaching operation in a single station and operation, the broach machine must perform the entire roughing, shaping, and finishing of the desired part profile in one step using a long, multi-piece, high-speed steel broach tool. The precise broaching and tooling cost per manufactured part is highly dependent upon the number of parts that can be manufactured between broach tool redressings. With tooling and redressing costs over the life of a helical broach bar on the order of $70,000 to $100,000, and total parts manufactured on a single broach bar currently in the range of 10,000 to 80,000 parts, the cost to broach a part is typically in the range of 60 cents to $5 or more. Hence, the broach tooling cost represents around 15 percent to 50 percent of the total manufacturing cost for a finished part.

Reduction of broaching costs is normally accomplished through developments of tooling materials, coatings, lubricants, and processing parameters without as much attention given to the influence of the material condition of the part being broached [2]. In order to study the influence of steel material condition on broach tooling life, a laboratory broach test machine was conceived, developed, built, and used to perform numerous studies on the broaching characteristics of various steel grades. This test method and results are described fully in References 3 and 4 and will be summarized here to illustrate the material impacts on machining costs.

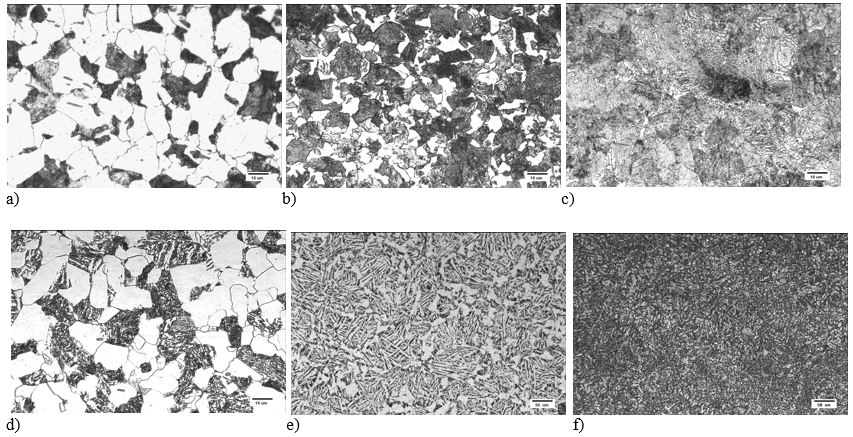

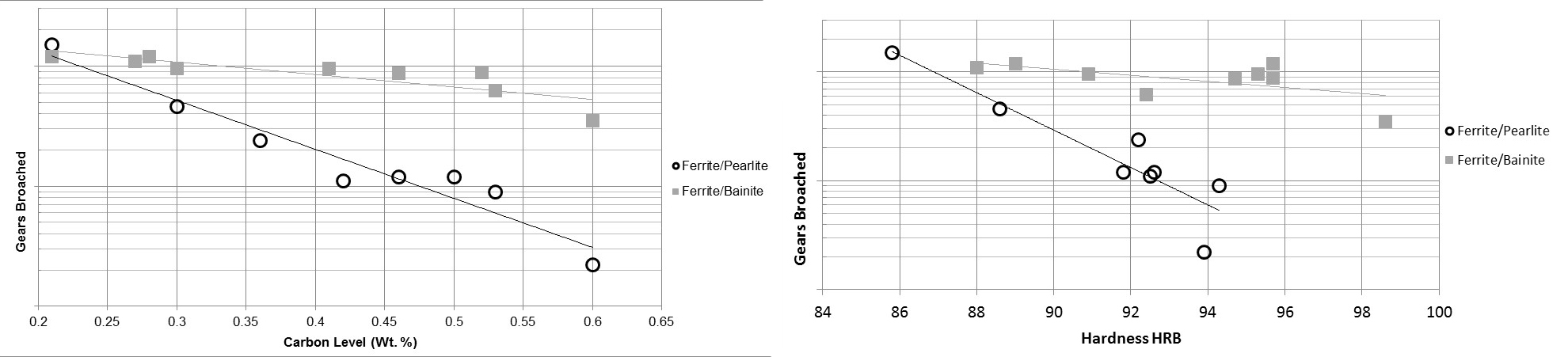

A series of steels typical of both carburizing and induction hardening gear applications were selected for testing. The steels were tested in both the typical baseline, ferrite/pearlite, and modified conditions (ferrite/non-pearlite or bainitic), with the intent to improve upon the baseline broach life results. These steels and the heat chemistries include low- to medium-carbon grades (0.20 to 0.60 wt. percent C), with varying alloying combinations (Mo, Cr, Cr-Mo, Cr-Ni-Mo, Mn, Mn-V) and hardness levels. The broach life results are shown in the attached plots for varying carbon and hardness levels and the two variant starting structures (ferrite/pearlite vs ferrite/non-pearlite). See Figure 1.

The non-pearlitic structure has been shown to achieve greatly increased broach life conditions over a similar range in carbon and hardness levels, as compared to the pearlitic conditions. These results allow for significant flexibility in steel selection and core hardness levels, while maintaining reasonable broach costs throughout. The non-pearlitic conditions develop an entirely different carbide structure as compared to the pearlitic carbides. The fine, spheroidal type carbides present in these tempered and non-tempered steels are much less abrasive to the broach tool, allowing for greatly enhanced tool life results. As such, using this technology would allow for achieving the low cost structure of the low carbon carburizing grades with the core properties and hardening characteristics required for higher carbon induction hardened gears. See Figure 2.

Summary

The costs associated with gear machining can be quite high, and where improvements with tooling advances alone are insufficient, material modifications may be useful to further reduce the overall machining costs. Whereas historically the raw material going into gear machining operations were annealed in a grade specific fashion, that is now sometimes being modified to result in the lowest overall cost to manufacture the gear application. These modified process routes are typically driven by improvements in machine tool and tooling advances, but additionally optimization of the gear blank material can result in large improvements in machining costs or increased options for manufacturing options and routes. The example of what has been accomplished for helically broached gears is summarized here, which can be used to improve broach tool life for a given application or used to determine cost optimized materials and process routes for new gears.

References

- C.V. De Motter, “The Art and Science of Broaching,” Gear Solutions, March 2007, pp. 30-35, 50.

- V. Schulze, H. Meier, T. Strauss and J. Gibmeier, “High Speed Broaching of Case Hardening Steel SAE 5120,” SciVerse Science Direct, 5th CIRP Conference on High Performance Cutting 2012, pp. 431-436.

- M. E. Burnett, “Enhanced Broaching Steel Technology,” SCT 2014, 4th Intl Conference on Steels on Cars and Trucks, June 15-19, 2014, Braunschweig, Germany, pp. 141-148.

- M. E. Burnett, “Improved Broaching Steel Technology,” Gear Technology, July 2016, pp. 44-49

About the author: Mike Burnett is a technologist at TimkenSteel. Learn more at www.timkensteel.com.