By the time you read this column, the 6th International Quenching and Control of Distortion Conference will have been concluded four weeks prior. Dozens of quality papers were presented discussing the technical aspects of distorting and how to measure, quantify and analyze the effect of the quenching processes with the obvious objective of one day being able to identify the “Holy Grail” of distortion: how to predict its repeatable effect on engineering materials. Also, assuming aliens haven’t abducted me, I will have made on October 2nd a presentation on catalytic gas nitriding [CGN] at Furnaces North America in Nashville, TN.

These two conferences illustrate the enormous effort being financed by academia and industry to understand how from the time man first discovered how to make a metal axe we still bend steel during quenching in ways we don’t want it to bend.

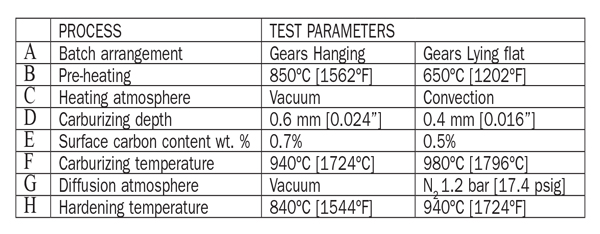

Of special interest to me from the quenching conference was a paper entitled: “Methodical investigation of distortion biasing parameters during case hardening of spur wheels” by Steinbacher, M., Surn, H., Clausen, B., Lübben, T., Hoffmann, F., Foundation Institute of Materials Science, Bremen, Germany. I’ve included, with some paraphrased portions of the paper here that analyzes the distortion measured on SAE 5120 [EN20MnCr5] steel carburized and quenched as follows:

• Low pressure carburization, [LPC] and 10 bar nitrogen quench

• LPC with oil quench

• Gas Carburizing with oil quench

• Gas Carbonitriding with oil quench

Testing conditions:

Regarding the test parameters above it’s a mystery to me why they elected to alter the parameters for the flat positioned gears vs. the hung gears. Direct quenching the flat gears from 940ºC [1724ºF] would certainly negatively affect the potential for distortion especially dishing distortion.

I won’t discuss all of the detail distortion findings but the most significant or greatest change from the green form. Many of the changes are not surprising when comparing the hung to flat positions. Without getting into the Fourier transformation data they site, for example, the dishing distortion for the hung gears was ½ that for the flat gears. The tooth profile change was greater for the deeper case depth and “higher quench from temperature” than the shallower case and lower temperature. And the overall growth or height and diameter change was greater for both hung and flat gears because of deeper martensite penetration due to the more severe oil quench vs. the 10 bar nitrogen. The gears tested were of small module, small enough that the 5120 steel could be case hardened with 10-bar nitrogen, not a very severe HPGQ when compared to 2-bar helium.

In order to more accurately isolate distortion characteristics in tests like that above, few parts are used so other parts do not influence the results; obviously from a scientific perspective that makes sense. As a consequence of this testing approach the learned data has limited application to real world production involving dozens or hundreds of parts stacked in layers or fixtured. This in my view is one reason why characterizing distortion in quenching has been so difficult to define.

Contrast again the investigation above with nitriding and you see why nitriding is continuing to gain market share as a case hardening process. Remember, nitriding at below the austenite region creates no distortion bending martensite when cooled; it only adds an extremely small uniform nitride layer over the entire gear exposed to ammonia. This is why I continue to be very interested in the patented Russian CGN process. I swap emails routinely with the CGN guru in Russia in an effort to understand and pass on all I can. Because the process confounds traditional nitride thinking due to the minuscule quantities of ammonia required, the accelerated processing times and the mind-bending simple process control, investigations in Russia are attempting to identify by gas analysis what is occurring differently inside the chamber compared to traditional nitriding. Experts who have witnessed the process first hand postulate theories but to date really have only that, theories. Put down the remote, there’s more to come.