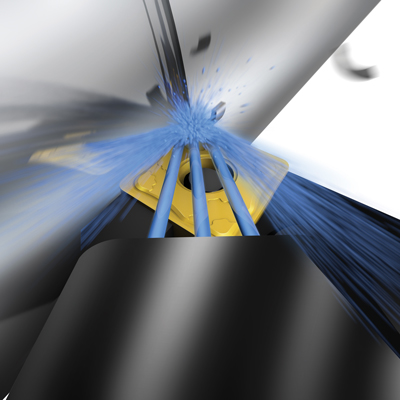

Sandvik Coromant introduces a range of new insert geometries and customized tool holders, featuring fixed nozzles that guarantee a precise coolant jet flow to get right to the center of the cutting zone.

Advanced Nozzle Technology The coolant flows from the pump to the tool through nozzles directed exactly at the cutting zone. This produces a wedge of coolant that efficiently removes the heat from the cutting zone and forms the chip. Improved chip control and longer tool life are just two of the benefits which contribute to secure, predictable machining and preventing unplanned machine stoppages.

The coolant flows from the pump to the tool through nozzles directed exactly at the cutting zone. This produces a wedge of coolant that efficiently removes the heat from the cutting zone and forms the chip. Improved chip control and longer tool life are just two of the benefits which contribute to secure, predictable machining and preventing unplanned machine stoppages.

Increased productivity can even be achieved in tricky applications and in materials that are difficult to machine, regardless of the pressure used.

When using low pressure of 5–30 bar (72–435 psi), the new Sandvik Coromant HP holders outperform regular tool holders, which have a tendency to flood coolant. At higher coolant pressures (above ~30 bar (435 psi)), the new insert geometry collects the coolant jets to form an even, powerful wedge that breaks the chips, cools the insert, and improves the insert tool life. The higher the pressure, the more difficult materials and applications can be machined with excellent results.

The Sandvik Coromant advanced cooling technology has, until now, been a solution primarily for customers using quick change with Coromant Capto®, SL-, and QS holding system. Now, the same premium technology can be applied with general shank tools, making it possible for everyone working with wet machining to utilize this highly productive coolant solution, even in small lathes. For more information, visit www.sandvik.coromant.com/us.