In booth 1321 at Houstex 2013, EXSYS Tool, Inc. will display a variety of advanced tooling solutions for CNC turning machines. Innovations include the company’s PRECI-FLEX® system, internal coolant cut-off blade toolholders, and gear hobbing system, as well as its double-square shank and quad-square shank static toolholders. Houstex 2013 takes place Feb. 26-28 in Houston, Texas at the George R. Brown Convention Center.

EXSYS’s industry-leading PRECI-FLEX toolholders offer fast, accurate, and cost-effective solutions for lathe tooling changeovers. It is the first system of its kind to have a single-base holder and multiple tooling adapters that utilize the ER collet pocket, virtually eliminating machine downtime and allowing for the interchanging of tooling adapters between fixed and rotary base holders. Available in a range of sizes, PRECI-FLEX provides unmatched flexibility, reliability, precision, and productivity in a compact, cost-saving design.

Attendees of Houstex can experience the internal coolant capable cut-off blade toolholder that channels coolant internally from machine turrets to internal-coolant cut-off blades and precisely into the cut zone. This design helps cut-off operations run cooler while improving surface finishes and shortening the overall part-processing times. This results in the elimination of any secondary operations required for the smoothing of rough surface finishes that arise from high heat and friction.

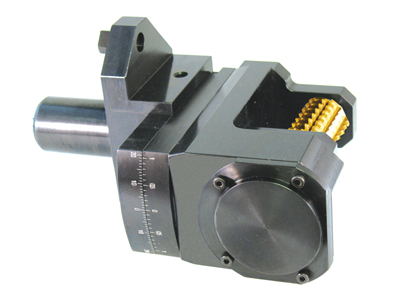

Also on display is the special compact gear hobber system, designed for use in Mazak horizontal turning centers. This EXSYS/EPPINGER adjustable tool holding system allows shops to generate splines, spurs, or helical gears in one operation. It eliminates the need to rough gears on one machine and transfer them to another for gear hobbing. In most instances, the system operates without interrupting its neighboring tool stations in a machine turret.

For increasing tooling capacity, the double-square shank and quad-square shank static toolholders from EXSYS allow for two or four inserts, as opposed to just one, in a single tool turret station. The double-square shank holder provides two turning inserts – one on the left side of its shank and another on the right side. The quad-square shank holder accommodates four inserts – two located on each side of its shank – for even greater tool capacity. Both holder styles save time and money by freeing up other stations and eliminating the need to index a machine’s turret for switching from one insert to the next when they are located in separate stations. For more information on EXSYS Tool, Inc. and its complete product portfolio, please visit www.exsys-tool.com.