A machine that runs endlessly without any wear and frictional losses — who wouldn’t dream of that? Unfortunately, such a machine does not exist yet. However classic car fans know that through solid technology and ongoing service, cars can even outlast their owners. However, this does not happen with machinery of all industries.

In the wind industry, statistics indicate that gearboxes need to be replaced two to three times during a 20-year period. They wear out due to high stress, unsuitable lubricants, and poor maintenance management faster than originally thought.

In the context of tribological properties of gears and bearings, Sentient Science held a presentation in Hamburg in 2016 on the lifetime calculation of wind-turbine gearboxes via the high-tech software called “DigitalClone.” Sentient Science introduced its conclusive proof that the lifetime of a WEA-gearbox can be extended by a factor of 2.6 to 3.3 by reducing the friction forces. The results obviously apply not only to gearboxes of a wind turbine but also to a variety of machines where friction and wear occurs.

Digital Clone

Sentient Science developed a material-science based predictive model of a GE 1.5 SLE Winergy 4410.2. This DigitalClone® gearbox model was used to study the fatigue life impact of Rewitec’s surface refinement technology DuraGear® W100. The lubricant is based on nano- and micro-particle bonding components and can be used not only in wind applications but also in industrial, shipping, and automotive applications. In the test with Sentient Science, the treatment was applied on surface-damaged bearings and gears of the Winergy gearbox. As a result of the measured reduction in surface damage, Sentient’s DigitalClone® technology predicts that Winergy 4410.2 gearboxes will exhibit a significant improvement in life compared to untreated gearboxes operating under field representative operating conditions.

Specifically for bearings, the treatment shows an improvement of the overall contact fatigue life by a factor of 3.3. For gears, the overall fatigue life is improved by a factor of 2.6.

Tribological Research

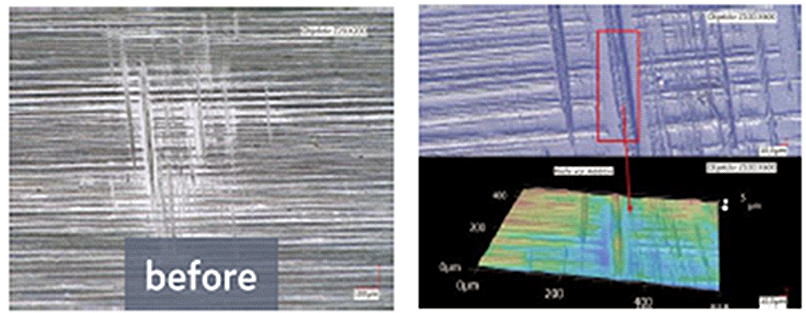

The first calculations for friction were done by Leonardo da Vinci at the beginning of the Modern Era. Nowadays, tribological fundamentals come from research institutes such as the Institute for Applied Physics of the University Gießen and the Competence Center for Tribology of Mannheim University of Applied Sciences, which investigate the friction phenomena with special testing machines and measuring methods. Dr. Paul Feinle, a researcher at Mannheim University, and his team found that roughness and friction (as well as wear and temperature rise) can be reduced by up to 43 percent with the support of specialty lubrications like the innovative nano- and micro-particle-based surface refinement technology from Rewitec.

The lubricant in this case acts as a means of transportation and carries the silicon coating onto loaded metal surfaces. By using friction energy and crystalline temperatures that arise in the so-called mixed friction range, the products passivate the surface and reduce the roughness. This increases the service life and safety of the systems.

This innovative technology ensures that life and machine performance are enhanced over the long term, and the wear in the tribological systems is reduced. Once added to the lubricant, the Rewitec products, specifically developed for each respective purpose, provide protection over many hours of operation. The concentrated active agents are generally supplied premixed in a neutral oil, which is compatible with practically all standard lubricants.

Examples of application Gear teeth

The meaning of Roughness

Less roughness of rubbing surfaces of bearings and gear teeth results in less friction. Less friction means less wear, and less wear prevents failures and system insecurity. This would certainly lead to positive effects as cost reduction, material and energy savings, less CO2 emissions, as well as greater sustainability. If roughness is the origin of the chain of negative effects, how is the problem solved?

The solution is called predictive maintenance, which is based on historical data and maturity calculations. The scientific material data comes from manufacturers of different components, which gain their information through online monitoring on the basis of real load collectives.

In addition to that, research institutes such as Mannheim University investigate the effect of lubrications containing certain additives on special test benches. With the support of this data, Rewitec was able to develop a treatment that contains life-extending properties able to minimize the roughness and its subsequent negative effects. The University of Mannheim and the University of Gießen proved that the roughness on treated interfaces were reduced by up to 55 percent. Equally significant was the reduction in the friction in gears and bearings by up to 43 percent. Corresponding to that was the fall in temperature and undesired vibration, as the results of vibration analyses showed.

Scientific tests

The Competence Center for Tribology of Mannheim University of Applied Sciences examined the effect of the specialty lubrication in gear oils under rolling-sliding motion with a rolling wear tester. The experiment was carried out on a modern two-disc test assembly that makes it possible to simulate tooth-flank operating conditions. The evaluation showed the extent of change in friction behavior and temperature after adding Rewitec to different high-performance PAO (Polyalphaolefines)-based gear oils. Each test was performed with and without the addition of the Rewitec® concentrate during 40 running hours. The first 20 running hours were performed without the concentrate and the next 20 running hours with the Rewitec® concentrate. On average, there was a lower surface roughness after treatment of 30 to 50 percent and up to 50 percent less friction.

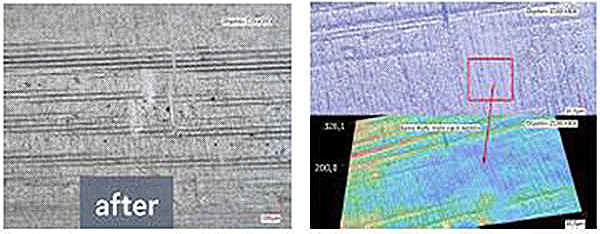

Example Result: Castrol Optigear Synthetic X320

In the first test round, the friction force increases steadily while running before adding the Rewitec® substance. After the substance is added, the friction force decreases by 22 percent. At the end of the test, the friction force still did not reach its minimum level (blue curve). Test run number two (red curve) shows what happens without adding the Rewitec® substance (Figure 3). The friction force increases steadily. After 40 hours, a constant friction force seems to be reached. In the third round, the Rewitec® substance is added at the beginning of the test run (green curve). The test run shows the effectivity of Rewitec® from the start up through 40 hours, and the friction force steadily decreases.

FE-8 test

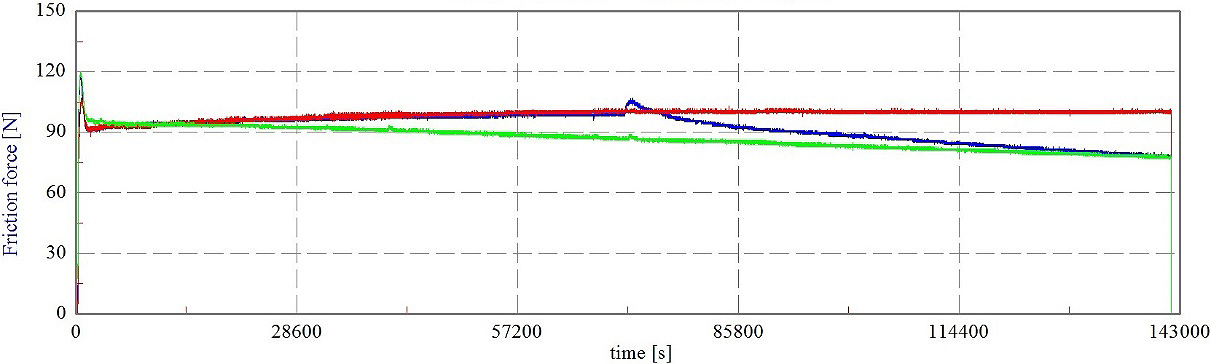

The FE-8 test is used to examine lubricating oils and greases to gauge their wear and friction behavior under lubricant and bearing-specific influences. To assess the suitability of the lubricant to be tested, the friction, the temperature, and the wear are determined through the resulting weight loss of the bearings in the test arrangement. The tests also allow the ability to perform surface measurements, lubricant performance, and reaction layer analyses. In addition, volume-based wear can be determined through weight measurement (Figure 4).

- Light run marks and smoother surface

- 17 percent less wear with the Rewitec®-concentrate

Mixed-ehl model

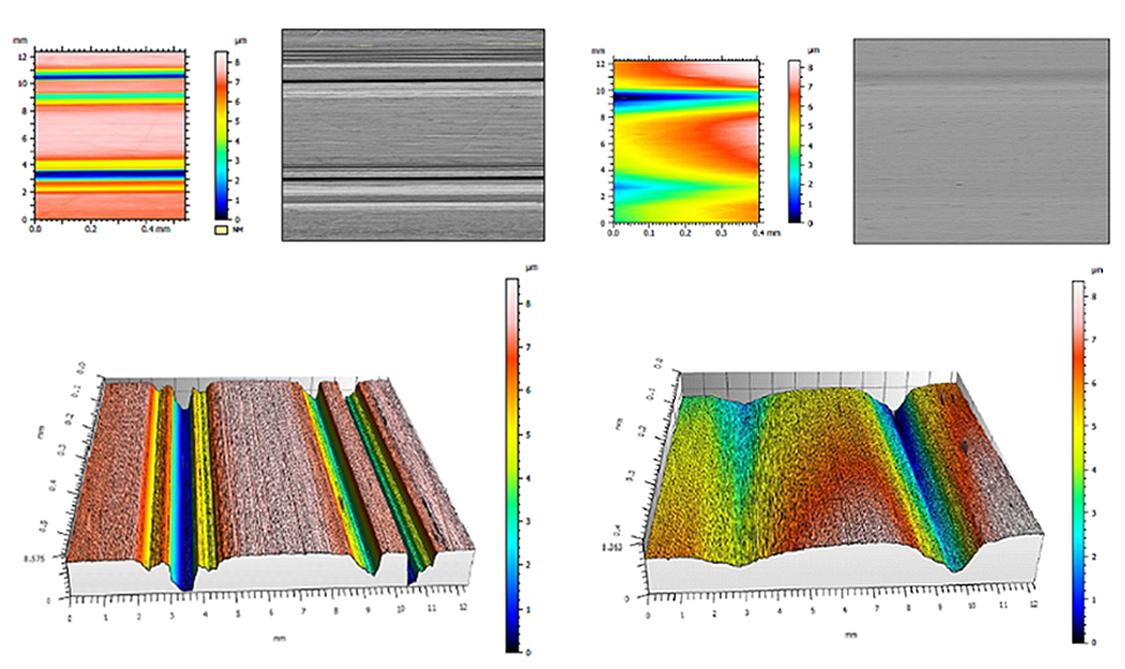

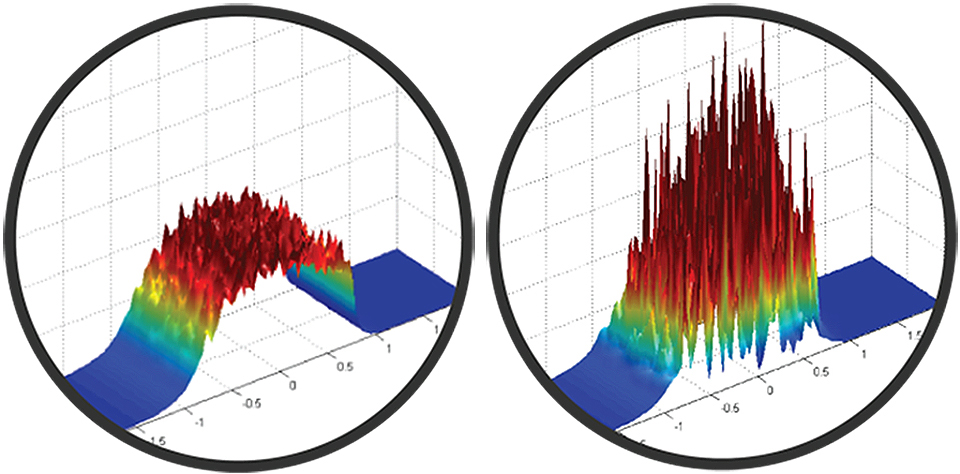

To take the influence of micro asperity into account for the determination of probabilistic fatigue life, Sentient Science used EHL (elastro-hydrodynamic-lubrication) solver, which uses simulated surface roughness profiles in an explicit deterministic calculation of surface tractions. Surface traction refers to the pressure transmitted between two surfaces through a lubricant.

Outcome: The performance of a given surface finish during the generation, sustainment, and/or failure of an EHL film at the contact zone can directly be determined.

Figure 5 illustrates the surface pressure of two such modeled rough surfaces interacting (left) and two (DuraGear treated) smooth surfaces interacting (right).

Field application

The company used Rewitec DuraGea W100 Gearbox Surface Protection to a gearbox after 10 months of operation. Based on the evaluation, the application of the Rewitec product resulted in an improvement to the surface structure and roughness of the tooth flanks, a reduction in run through marks, micropitting and seizure and the electrical resistance from the gearbox improved significantly.

“In dealing with Rewitec products, experience has shown that the wear of our wind turbines is signifi- cantly delayed,” said Jochen Holling, mechanical engineer, global technical support and engineering, Availon GmbH. “In most cases, the progressive damage in certain gearboxes and bearings with pre-mechanical damage was even eliminated.”

About the author ipl.-Ing. Stefan Bill is managing director and an executive partner of Rewitec® GmbH, Lahnau. His company was a finalist in the 28th Innovations Awards of the German Economy 2007. He received the 1st HUSUM Wind Energy Award in 2009, the Industry Award 2014 Category — Best of 2014 for DuraGear®, Finalist Wind Energy Award 2016 — Supplier of the Year.