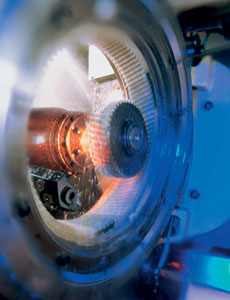

Gleason has introduced a new series of Opti-Form® honing wheels that reduce the time typically required to perform the initial tool dressing by as much as 50 percent, while at the same time improving both the tool life of the honing wheel and the master gear used for dressing. Conventional honing wheels generally require a slow, tedious initial dressing process to finish form the wheel with the required gear tooth characteristics. This can take as long as 45 minutes to complete, during which the honing machine is not producing parts. But by using the new Gleason Opti-Form honing wheels end users can eliminate as much as half of this time since the wheels arrive with critical features like profile, lead crowning, and low run-out already produced in advance using an exclusive process developed by Gleason-HURTH. Learn more at [www.gleason.com].

Gleason has introduced a new series of Opti-Form® honing wheels that reduce the time typically required to perform the initial tool dressing by as much as 50 percent, while at the same time improving both the tool life of the honing wheel and the master gear used for dressing. Conventional honing wheels generally require a slow, tedious initial dressing process to finish form the wheel with the required gear tooth characteristics. This can take as long as 45 minutes to complete, during which the honing machine is not producing parts. But by using the new Gleason Opti-Form honing wheels end users can eliminate as much as half of this time since the wheels arrive with critical features like profile, lead crowning, and low run-out already produced in advance using an exclusive process developed by Gleason-HURTH. Learn more at [www.gleason.com].

Welcome!Log into your account