Affolter Technologies SA, a technology leader in micro-gear hobbing centers for the watchmaking and micromechanical industries, launches a groundbreaking innovation: Worm Screw Power Skiving (WSPS).

“This cutting-edge technology was developed by our engineering experts in an intensive R&D process,” said Managing Director Vincent Affolter. “Worm Screw Power Skiving allows us to finish a high-precision worm in only six seconds. If done by worm hobbing, every piece will take 25 seconds.”

In other words: WSPS can make the producers four times more efficient.

In other words: WSPS can make the producers four times more efficient.

“This will increase the productivity and efficiency of manufacturers in the automotive and aircraft industries considerably,” said Affolter.

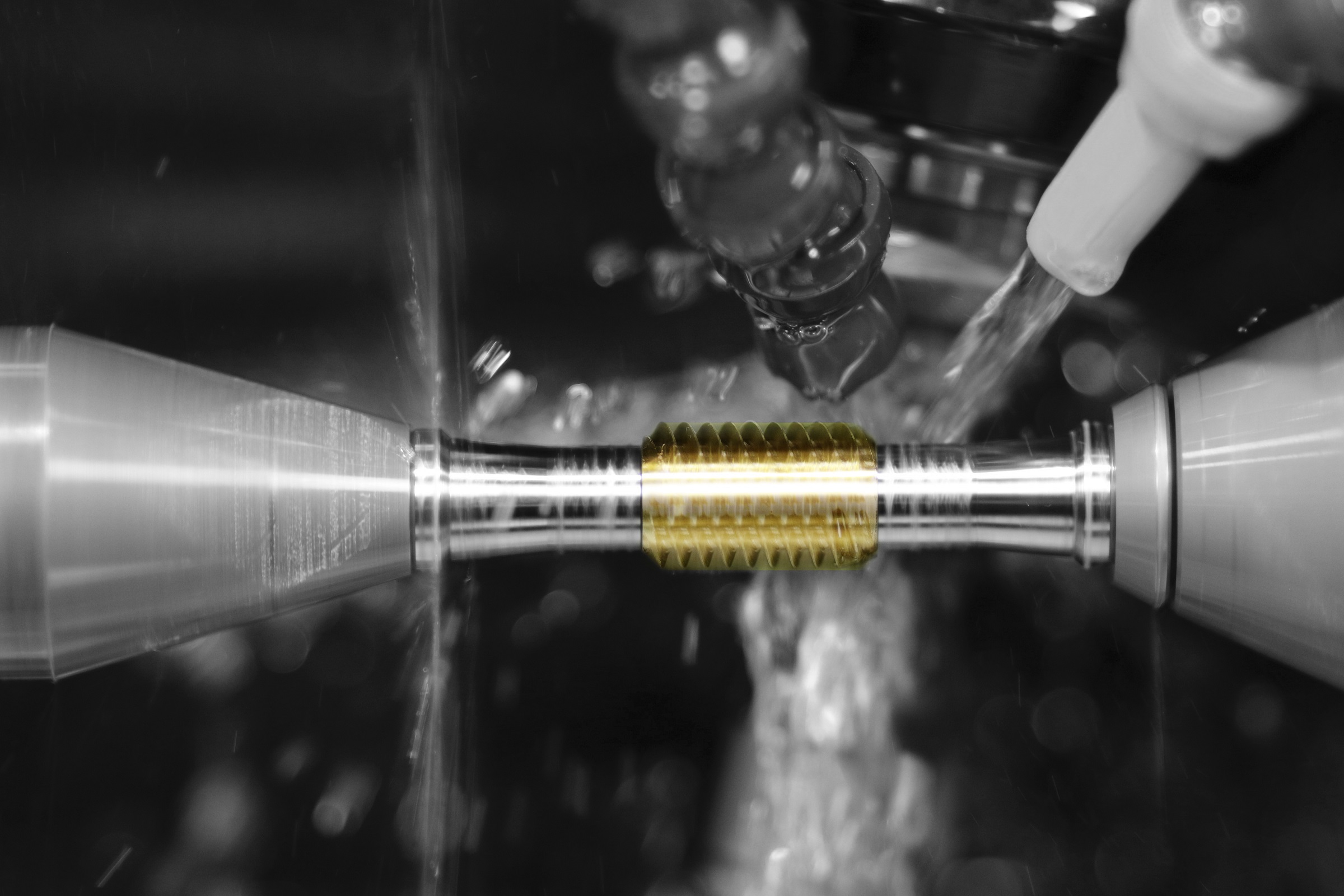

Many producers in these industries need to manufacture large quantities of high-precision worms. The WSPS technology focuses on small worms with a module of 0.3 to 1.5.

“Such worms are used in car seats or trunks, for instance,” said Affolter. “We see a big demand in the automotive industry, but also in other sectors.”

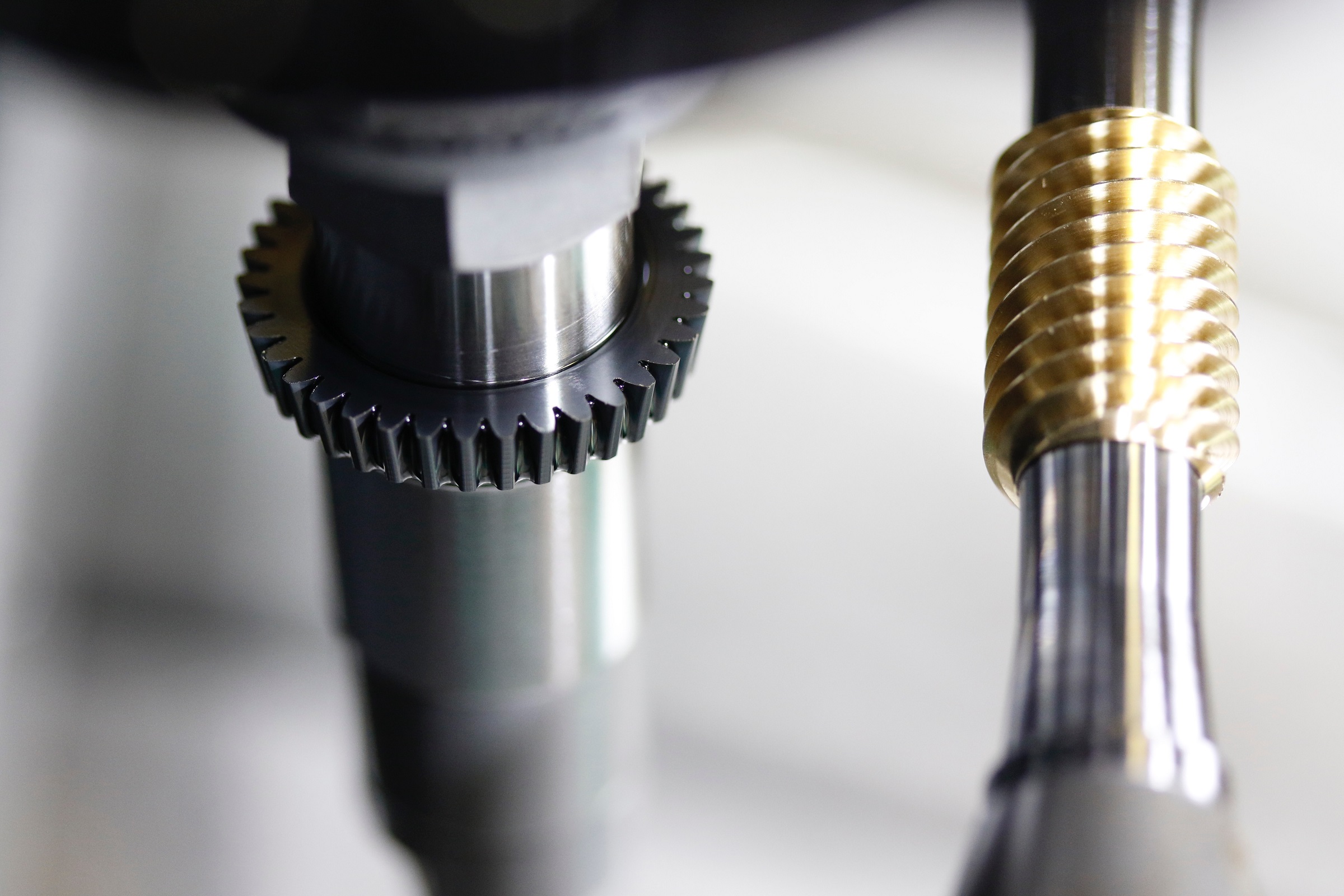

The idea behind the new technology: Unlike in worm hobbing, where the hob turns much faster than the workpiece, the Affolter experts inverted the process.

“The workpiece turns extremely fast, with two new spindles up to 12,000 rpm, while the cutter turns much slower,” Affolter said. “Only highest quality machines like the Affolter AF100 Plus and AF110 Plus can reach this speed and at the same time provide the necessary stiffness.”

The Affolter engineers have redesigned the well-established gear line model AF110 to optimize the WSPS process. The result is the brand-new gear hobbing machine AF110 Plus. The workpiece spindles were successfully remodeled to reach the high speeds needed. The Affolter marketing and R&D team also focused on completely redesigning the machine.

“We integrated a cutting fluid filtration system and a chip disposal solution,” Affolter said. “This allows us to cope with all the requirements imposed by the workpiece up to module 1.5 and the production of large volumes of chips.”

Additionally, the Affolter engineers and the marketing team improved the ergonomics through a redefinition of the machine base and surrounding as well as the human-machine interface. The flexible AF110 Plus has a function that allows it to operate at reduced speeds with the hood open (full-safety setup machine mode).

“We achieved outstanding results processing both steel and brass,” Affolter said. “The new AF110 Plus and the WSPS technology will open completely new opportunities for our customers.”

Affolter will present the WSPS technology at IMTS in Chicago on September 12-17 (Hall N, #Booth 7223). The distributor of Affolter Technologies SA in the United States is Rotec Tools based in Mahopac, New York.