Oil quenchants have been used extensively to harden steel in excess of 100 years. There are a wide variety of commercially available quenchants on the market, from nearly as many different producers. This column explores how the chemistry of the base oil and additive package affects quenching performance. A discussion of the mechanism of oil degradation also will be provided. This will be broken into two sections: first a description of quench oils, and the second part will be a description of the oxidation of quench oil and ramifications for the heat treater.

Many types of oils have been used for quenching, including vegetable, fish and animal oils, and particularly sperm whale oil have been used for quenching operations. The first petroleum-based quenching oils were developed about in 1880 by E.F. Houghton in Philadelphia. Since that time, many advancements have been made in the development of quenching oils to provide highly specialized products for specific applications.

A wide range of quenching characteristics can be obtained through careful formulation and manufacturing. High quality quenching oils are formulated from refined base stocks of high thermal stability. Selected wetting agents, antioxidants, and accelerators are added to achieve specific quenching characteristics. The additions of these complex anti-oxidant packages are included to maintain performance for long periods of continued use, particularly at elevated temperatures. Emulsifiers may be added to enable easy cleaning after quenching.

Petroleum-based quench oils can be divided into several categories, such as quenching speed, operating temperatures, and ease of removal. The simplest category is operational temperature: Cold oils for operation below 90° C and mar-tempering oils used for temperatures above 90° C.

Cold oils are the most widely used oils for heat-treating applications. These oils are further broken down into rankings according to speed or heat extraction. These are usually called slow-, medium-, and high-speed oils.

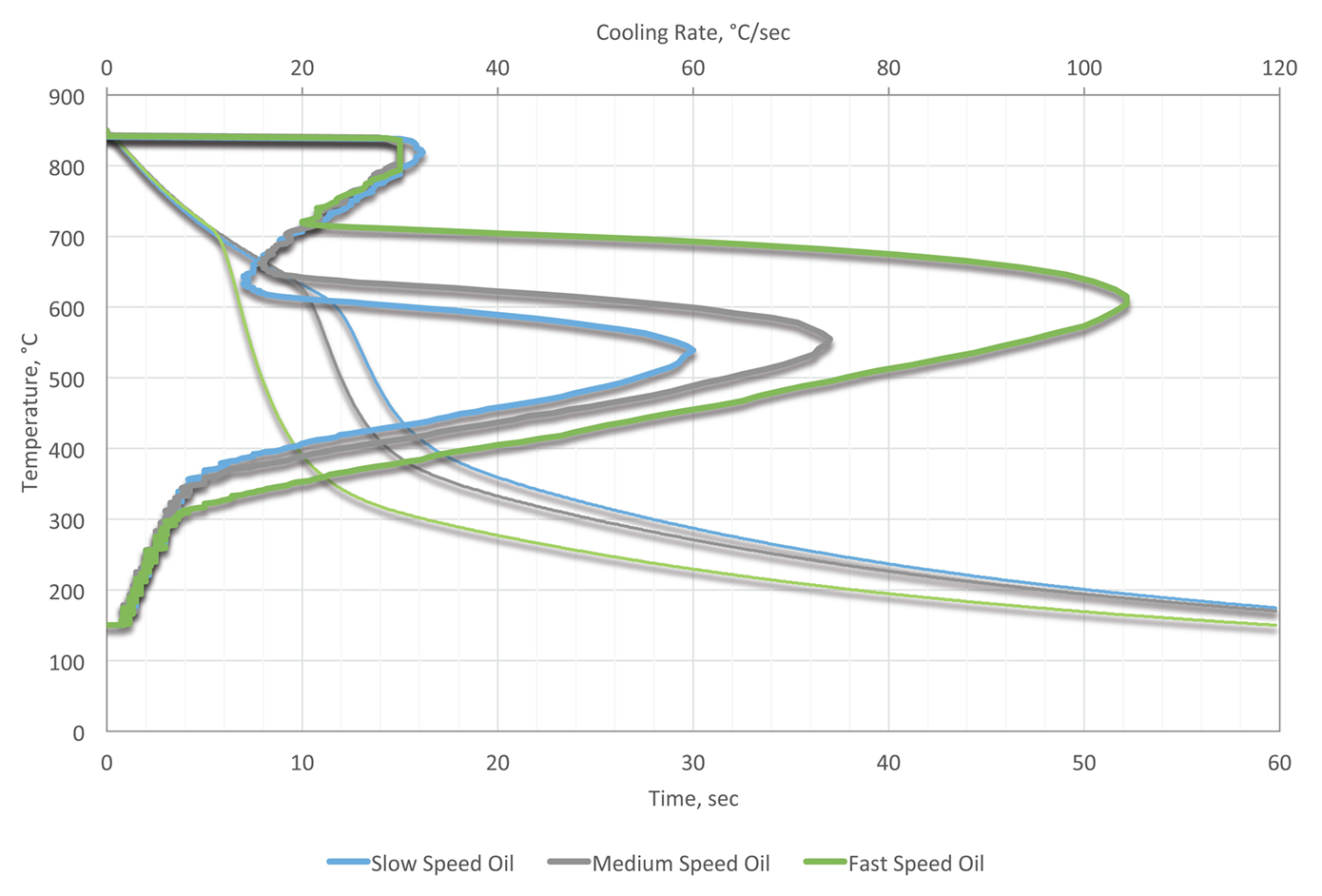

Normal-speed quench oils have relatively low rates of heat extraction and are used in applications where the material being quenched has a high hardenability. Highly alloyed steels such as AISI 4340 or tool steels are typical examples of steels quenched in normal speed oils. These oils usually have a maximum quench rate below approximately 60° C/s (108° F/s).

Medium-speed quench oils provide intermediate quenching characteristics and are widely used for medium to high hardenability applications where dependable, consistent metallurgical properties are required. These oils have a maximum cooling rate between 60° C/s to 90° C/s (108° F/s to 162° F/s). This is the most widely used group of cold oils, primarily because of the wide applicability.

High-speed quench oils are used for applications such as low hardenability alloys, carburized, and carbo-nitrided components, or large cross-sections of medium hardenability steels where high rates of cooling are required to ensure maximum mechanical properties. High-speed quench oils usually have a maximum cooling rate greater than 90° C/s (162° F/s). A comparison of the quenching speeds of the different types of quench oil is shown in Figure 1.

Mar-quenching oils are a special case where the part is quenched into a quenchant at elevated temperature, typically 100° to 200° C. The work piece is held in the quenchant until temperature equilibrium is established throughout the section and then air-cooled to ambient temperature. During mar-quenching, components are quenched to an intermediate temperature close to the Martensite start (Ms) temperature and held at this temperature. This eliminates the temperature gradients across the surface, and consequently, during subsequent slow cooling after removal from the hot oil, transformation to Martensite occurs uniformly throughout the section. This minimizes the generation of internal stresses and reduces distortion.

Since mar-quenching oils are used at relatively high temperatures, their formulation and physical properties are different from cold quenching oils. They are formulated from carefully selected base stocks with high oxidation resistance and thermal stability. They have high flash points and viscosities and contain complex anti-oxidant packages to provide long life. Selection of the mar-quenching oil is based on the operating temperature and quenching characteristics. A minimum of 50º C should be maintained between the operating temperature of the oil and its flash point.

Additive Packages

Additive packages have two functions: first to act as a speed improver, and second to increase thermal and oxidative stability. These additives can have a dramatic effect on the quenching properties. The magnitude of the effect is dependent on the additive package. These additive packages are usually proprietary. Depending on the robustness of the additive package, they may tend to deplete during use. Some additive packages are prone to selective drag-out over time. It’s generally not appropriate to mix additive packages from different quenchant suppliers because of the unintended consequences of precipitation, increased staining, and generally unpredictable response.

Speed improvers increase the quenching rates by increasing the wettability of the oil. There are different types of additives. The most common is the sulfonate-type. Barium sulfonate used to be the most common, but it is no longer used by most quenchant suppliers. The presence of barium can cause an issue with disposal and special precautions during disposal. Potassium and sodium sulfonates are commonly used. These sulfonates provide excellent speed improvement and can double as thermal oxidation stabilizers. However, if oil is recovered from washers and reused (after eliminating water), the soluble sodium sulfonates can be depleted from the quench oil. This can lead to a greater emulsified layer of oil in the washer, contributing to poor recovery yield. It can also

contribute to poorly washed parts. Hydrocarbon based additive packages are used in high-end quenchants. They are robust and have a long life and are not prone to replenishment. The primary disadvantage is cost.

The other purpose of an additive package is to improve the thermal and oxidative stability of the base oil. These packages reduce the formation of sludge and minimize the formation of organic acids upon thermal aging of the oil.

Conclusions

In this column the different types of quench oil were described, and the constituents in commercially available quench oil examined. Part 2 will address base oils, while the oxidation of oils and the interaction of anti-oxidants will be discussed in upcoming installments.

About the author: D. Scott MacKenzie, Ph.D., FAS, is senior research scientist-metallurgy at Houghton International Inc.

Go online to www.houghtonintl.com.