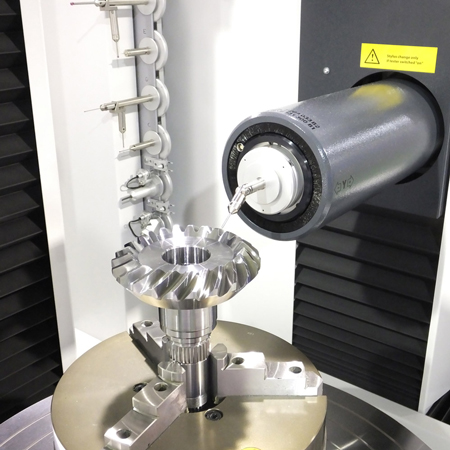

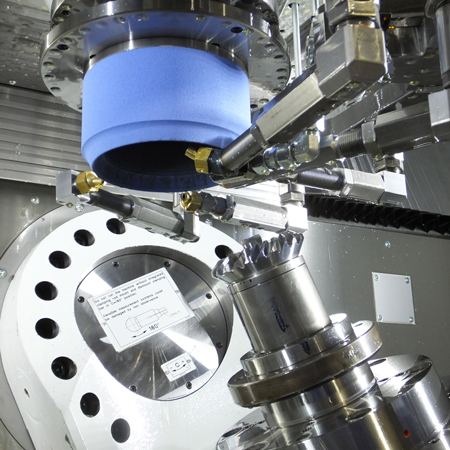

With efficiency increasingly key to automotive applications the world-over, Hewland Engineering announced the installation of a state-of-the-art Klingelnberg Oerlikon G60 Spiral Bevel Gear Grinding Machine. Utilizing Klingelnberg’s advanced KIMOS closed-loop manufacturing system, the G60 consistently produces efficient, durable gears through its highly accurate and repeatable manufacturing process.

Now completing its first components, the new machine will herald a new era of performance for Hewland clients, offering considerable improvements in efficiency, reduced gearbox temperatures, and above all, substantially increased component life.

Now completing its first components, the new machine will herald a new era of performance for Hewland clients, offering considerable improvements in efficiency, reduced gearbox temperatures, and above all, substantially increased component life.

Key capabilities include:

• Grinding of forms up to 600 mm in diameter

• Consistent grinding to DIN4 standard and above

• Grinding of spiral, hypoid, and Zerol bevel forms

• Closed-loop KIMOS system minimizes manufacturing errors

Hewland also expands its gear inspection capabilities with an all-new Klingelnberg P65 Gear Measuring Center that will measure gear profiles up to 650 mm in diameter, working in tandem with the G60 to offer vastly improved spiral bevel accuracy and consistency.

For bespoke and made-to-drawing applications, new software will reduce setup times, with on-machine dress-able grinding wheels negating the need for bespoke tooling.  The resultant reduction in lead times, combined with the improved performance from ground-finished parts, will be of substantial benefit to clients. The increased capacity brought about by this investment will help serve the market demand for both precision-ground and conventionally cut, high-quality bevels.

The resultant reduction in lead times, combined with the improved performance from ground-finished parts, will be of substantial benefit to clients. The increased capacity brought about by this investment will help serve the market demand for both precision-ground and conventionally cut, high-quality bevels.

Company Chairman William Hewland said that this latest investment will serve to highlight Hewland’s expertise as a center for precision manufacturing.

“Driven by a desire for increasingly efficient and durable transmission solutions, this latest investment will deliver consistent and highly accurate bevel gears for motorsport, defense, marine, and aerospace applications,” Hewland said. “Also boosting our manufacturing capabilities, the new precision grinding suite will ensure we continue to expand our offering of high-specification yet cost-sensitive make-to-print services.”

Hewland provides bespoke transmission solutions to some of the world’s leading motorsport companies, vehicles, and series, including the DTM, GT500, GP2, GP3, GT, LMP, Rally, and Formula E market segments. In addition to complete solutions, Hewland promotes its precision-engineering capabilities in aviation, OEM road-car, and Formula One, while specializing in advanced research and development consultancy services to the electric vehicle sector.

FOR MORE INFORMATION: www.hewland.com