The Swiss company, Reishauer, has shaped industrial history since its foundation in 1788. Originally, the company was set up as a smithy to make hand tools. In 1863, a “taps-lathe” was built to make the first threading taps with a radial relieving unit. With the growth of the tap market share, the company was well positioned to develop its first grinding machine in 1928: a thread-grinding machine with a single rib vitrified grinding wheel. The trigger to develop this machine was a lack of equipment on the market that could deliver the necessary accuracy for thread gauges. At this time, the market had no machine on offer that could efficiently grind threading taps. Hence, the dissatisfaction with existing technology triggered Reishauer engineers to develop a new type of thread-grinding machine. In 1931, the first machine went into production that was able to grind from solid hardened blanks, including the grinding of the relief angle.

This thread-grinding machine required precision gears for setting the pitch of the different threads on taps. The precision of the threads was directly related to the accuracy of the gears within the machine. Again, it was the dissatisfaction with the status quo of technology that drove the engineers to find a better way to manufacture high precision gears. This dissatisfaction led them to the invention of a new idea of gear grinding: the continuous generating process of grinding gear profiles, a process Reishauer has been famous for ever since. This process delivered gears that were more accurate, cheaper, and faster to manufacture than by the previous methods of tediously grinding gears tooth gap by tooth gap. Nevertheless, it took 15 years of intensive development work, and in 1945 the first continuous-generating gear grinding machines were used in-house and sold to third parties. The success of the thread and gear-grinding machines prompted Reishauer to halt tool manufacture and concentrate exclusively on building machine tools. Moreover, as the cost per gear ground diminished with increasing efficiency of the generating grinding process, automotive gear grinding gained more interest. In 2006, the company decided to concentrate fully on gear-grinding machines when the manufacture of thread grinders stopped.

In 1998, a familiar pattern of dissatisfaction with the status quo repeated itself, but in reverse order. The available tools for the gear-grinding machines, both grinding wheels and diamond dressing tools, could no longer match the performance potential of the continuous generating machines, particularly in accuracy. For this reason, Reishauer began its production of diamond dressing tools and laid the foundation of its performance portfolio that included machine tools and the required tooling. In 2008, a grinding wheel factory was founded, shortly followed in 2012 by a manufacturing site for fixturing. These steps ensured the full potential of the machine tools to deliver consistent quality at low costs per gear ground. Furthermore, this put Reishauer into a position of being able to control all factors that influence the quality of the continuous generating grinding process. The mindset to view tooling and machine tools separately no longer corresponded to modern thinking.

Grinding Wheels

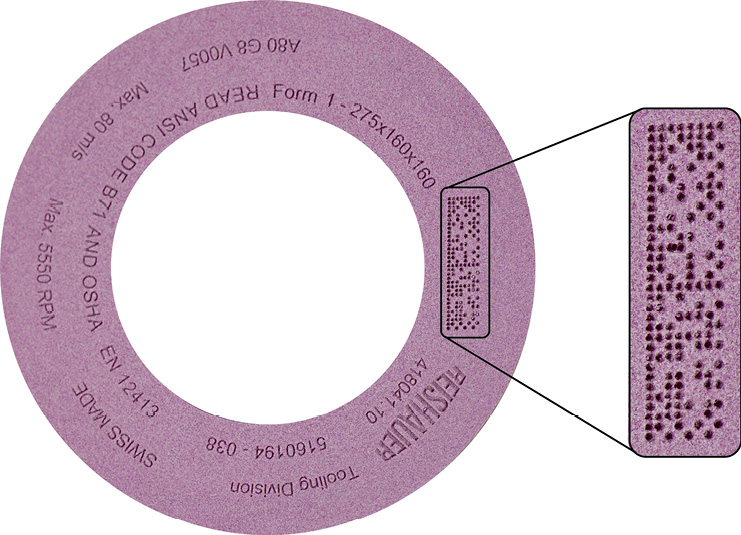

As the Greek philosopher Aristotle stated: “Every tool achieves perfection by serving one, instead of many purposes.” The company strictly adheres to this advice and limits itself to the manufacture of tooling that serves only one purpose: to grind high precision gears on Reishauer machines. The grinding wheels, also called “threaded wheels” once they have been profiled, play a vital role in the generating process. The grinding machine delivers the kinematics, i.e. the high precision movements that control the cutting path of the grinding wheel. For its part, the grinding wheel must transfer these precision movements onto the gear to be ground, by grinding this precisely to a predetermined dimension, surface finish, and structure, and within a short cycle time and without causing thermal damage. To meet these requirements, Reishauer has built one of the most modern and most automated grinding wheel factories in the world in Switzerland. In contrast to other wheel makers, Reishauer had the advantage to deal with only a few wheel dimensions and only one field of application, which made possible this high degree of automation. The extensive use of robotics ensures uncompromising homogeneity of the finished products as established grinding processes in customer plants that depend on this high degree of homogeneity from lot size to lot size. After pressing, each grinding wheel is laser-marked as soon as it leaves the pressing mold. This laser mark is a machine readable, indelible “birth certificate” (Illustration 2). This marking allows total control over each subsequent processing step and makes each grinding wheel traceable to ensure the tool delivers the consistent performance that end-users demand.

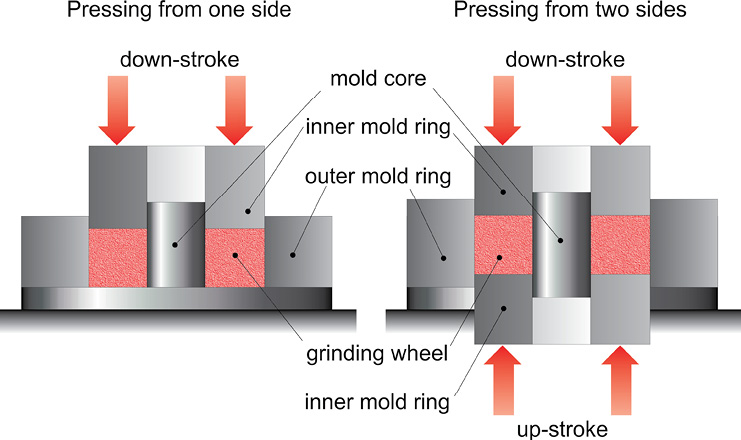

Contrary to conventional one-sided pressing operations, Reishauer wheels are made on presses and mold set-ups that allow pressing from top and bottom on a simultaneous down and up stroke press. This ensures the resulting hardness gradient across the full width of the wheel is minimal.

The loading of a kiln cart serves as a concrete example. Vitrified grinding wheels are fired for several days at a temperature marginally below 1,000°C (1,800°F), following a carefully established temperature curve, with defined ramp, holding and cooling-down temperature gradients. Before firing in the kiln, a robot places each grinding wheel at a specific position on the kiln cart (Illustration 5). The robot reads and records the position of each wheel, which can be retraced if required in the future. Knowing the position of each wheel during the firing process in the kiln, and subsequently measuring the hardness (modulus of elasticity) of each wheel, allows working out the firing conditions in such a way that all wheels have the same resulting hardness.

The comprehensive process monitoring covers all subsequent manufacturing steps such as hardness testing, turning, and speed testing. Over-speeding, i.e. speed testing each wheel, ensures the safety of the grinding processes at end users. In line with the relevant safety laws, Reishauer subjects every wheel to an automated over-speeding test with a safety factor of 1.5 times the permissible operating speed. Again, given the machine-readable wheel markings, each wheel speed test remains traceable.

Diamond dressing tools in symbiosis with the grinding wheel and the machine tool

Before a grinding wheel can deliver the required accuracy and material removal rate, it must be dressed by a high-precision rotary diamond dressing tool. The dressing of the threaded wheel for continuous generation, grinding meets several requirements. Firstly, dressing imparts a perfect worm profile and makes the threaded wheel free cutting. Secondly, dressing removes any impurities or wear that may have been instigated by the grinding process, such as the wheel pores stay open to accommodate grinding oil and can remove the chips that have been generated during the high material removal rates. Diamond is the ideal material for dressing tools, as it is much harder than the aluminum oxide of the threaded grinding wheels employed in the process.

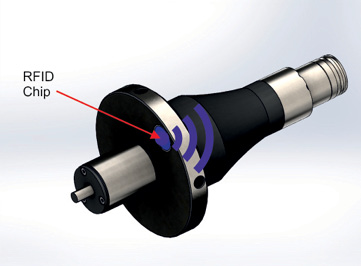

Only rotary dressing rolls can match the high requirements regarding geometry, service life, and efficiency during the dressing process. Illustration 6 shows a multi-start, reverse-plated diamond dresser. Additionally, this dresser is equipped with an RFID chip that can communicate with the machine.

Radio Frequency Identification (RFID) built into dressing tools serves, among other things, to generate and utilize usage data. The number of potentially remaining dressing cycles is stored in the dressing tool and can be read and accounted for by the machine. This offers the end users an overview of the potential remaining dressing life, allowing stock management and determining when new tooling should be ordered. Furthermore, the RFID chip also stores all the geometrical data of the dressing tool, which is directly read by the machine. For these reasons, input data errors are eradicated. Additionally, the end users can choose from further options such as connections to internal and external tooling databases.

Work Holding

Precision gear grinding results depend on fixturing of equal high precision, which only hydraulic expanding can deliver with a repeatability of ≤ 3 micrometers. To maintain control over the whole gear-grinding process, Reishauer decided to make its own fixturing. The clamping tools are tailor-made to specific parts. The hydraulic expansion mandrels can be coupled to quick-change bases if a frequent part changeover is required. This system reduces set-up times and increases productivity, translating into an economical use of the continuous gear-grinding machine for small or large batch production.

As described for the diamond dressing tools, the fixturing also can be fitted with RFID chips and the resulting system “machine tool – fixturing – grinding wheel – dressing tool” makes for a grinding process perfectly adapted to the highest quality requirement both in accuracy and in short cycle times. The RFID option allows the tracking of the number of fixturing operations, the monitoring of maximum and minimum clamping pressures, and the integration of preventive maintenance. Furthermore, for a known part, the part data stored in the clamping tool can assist the machine tool to move automatically into the correct set-up positions.

Made in Switzerland

The high degree of in-house manufacturing or vertical integration is the foundation of the Reishauer performance portfolio. All core components are developed in-house and manufactured in Switzerland. In this way, the continuous generating process will hold its leading edge as the superior hard-finishing method for making gears.