With many years of development, generating gear grinding is at a highly evolved point. It is no longer a question of any mainline gear grinder being able to produce a high-quality gear. Grinding times from various manufacturers are all within a tight range. In this race, all the top competitors are neck-and-neck. Has stasis been reached? This article illustrates that progress never stops in gear grinding.

A Little Background

Mitsubishi Heavy Industries Machine Tool Co., Ltd., of Japan, has been manufacturing generating gear grinding machines since 1966 when they began production of the model “NZA” under license for the domestic market in Japan. That arrangement ran its course, and MHI developed their ZE series of generating grinders, which launched globally in 2005. Since then, nearly 500 gear grinding machines have been produced and installed worldwide. In addition, MHI developed the first and only generating grinder for internal gears, the ZI20A, which debuted in 2009. As a machine tool builder, MHI has produced thousands of other machines: hobbers, shapers, gear skiving machines, shavers, OD grinders, and large milling machines.

Small Improvements Yield Big Results

As might be expected of a Japanese company, continuous improvement, or “kaizen,” is part of the corporate culture. Already the clear leader in reliability, the goal for the new machines is to triple MTBF (mean time between failures) and reduce MTTR (mean time to repair) by half. MHI works closely with the major Japanese automakers and suppliers on these kaizen activities to further reduce downtime and improve maintainability of the hundreds of current gear grinders already installed, and to build even more reliability into future models as well.

From the Inside Out

During the development of the upcoming new generating grinders from MHI, the ZE16C (Figure 1) and ZE26C, cables and connectors came under scrutiny and were improved. The newest materials for cables and connectors are used to resist oils and coolants. These were extensively tested in actual machining conditions to prove them out. A small change to be sure, but this adds to reliability and improves MTBF and reduces TCO (Total Cost of Ownership).

The location of sensors and wiring inside the working area of a grinder exposes them to oil or coolant and swarf. Engineering was undertaken to minimize this for the new models, and the working area has no unnecessary wiring or sensors.

Access to key components was improved by mounting the electrical control cabinet on the side of the machine. The cabinet swings away from the machine to provide easy access and maintainability along with the reduced floor space needed.

Input from customers guided the development of a special fixture that allows the removal of tool spindles if necessary without the use of an overhead crane or hoist. As a result, the time to repair is reduced.

Improvements to Productivity

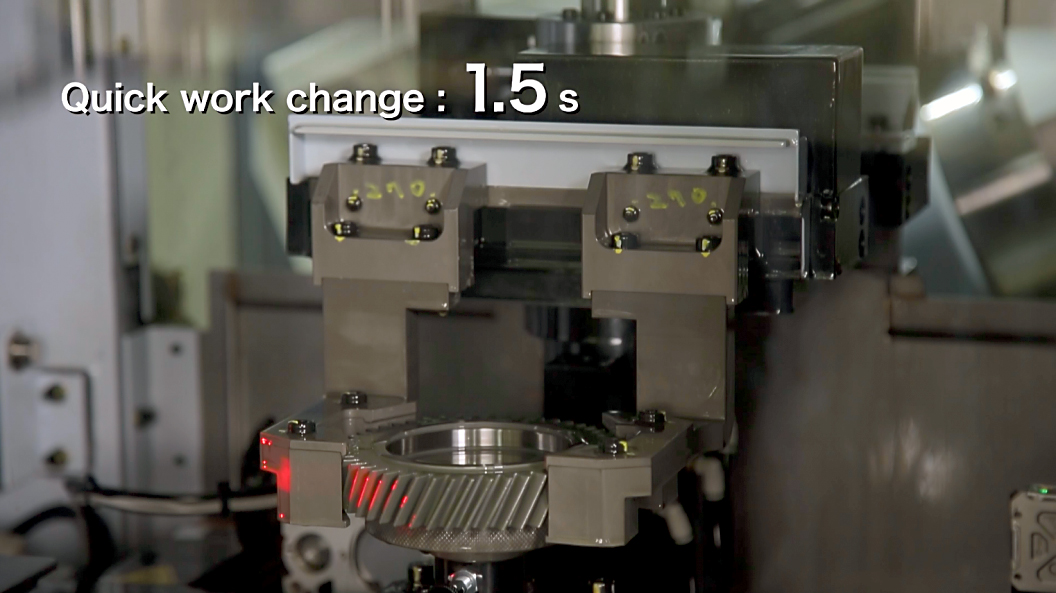

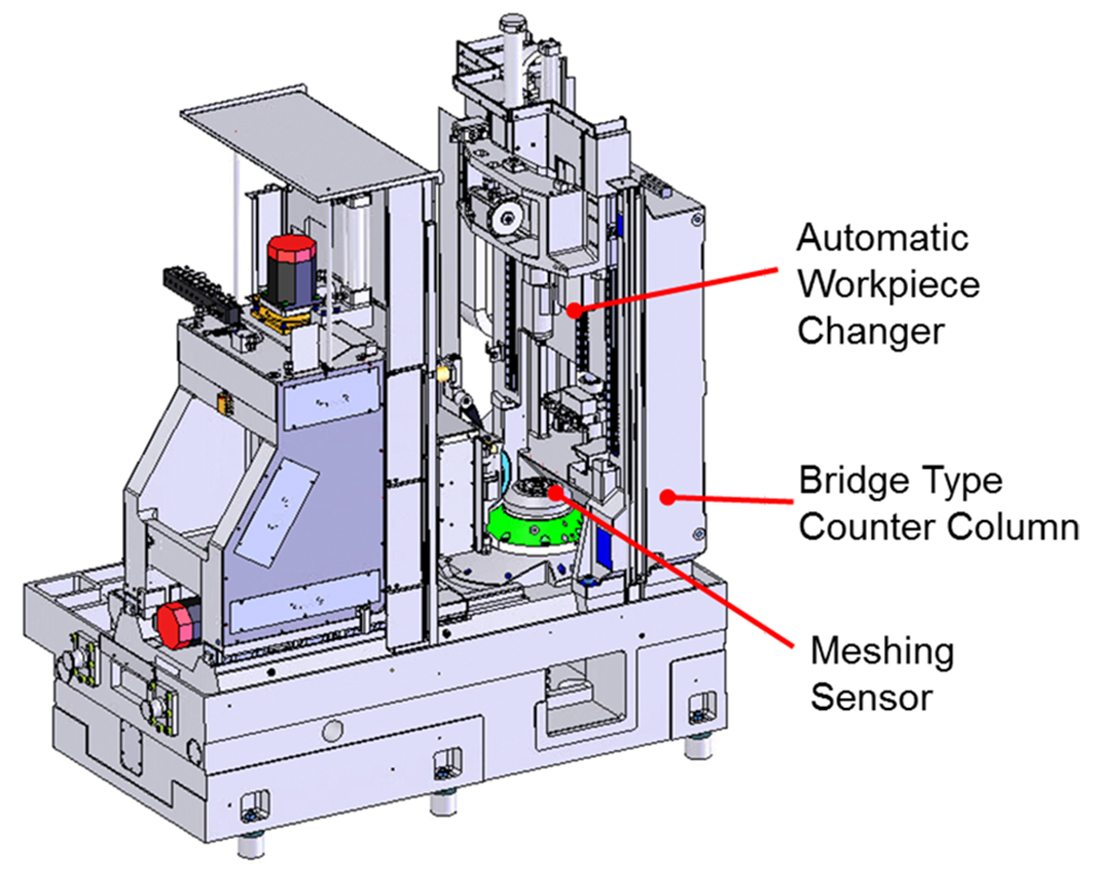

High volume gear manufacturing demands maximum process stability from gear grinders. The single spindle design of the ZE16C and 26C provides unmatched Cp and CpK performance. Non-grinding time is reduced by using a high-speed part changing system with a small rotation radius (Figure 2). On the ZE16C, part exchange times of 1.5 seconds are now available.

Further improvement in speed is realized by the development of an ultra-high-speed processor board for stock dividing and meshing the grinding wheel with the part. The part sensing cycle can be accomplished at full grinding speeds, eliminating the acceleration and deceleration of the work table.

The ZE16C, designed for high volume production of pinion and transfer drive gears, is equipped with a bridge type counter column (Figure 3). Locating the meshing sensor on the counter column permits the simultaneous operation of tooth sensing/stock divide and grinding column movement, further reducing non-grinding time.

The strength and stability of the counter column was extensively modeled during the design phase. Instrumented testing has confirmed the resulting superior machine stability and resulting part accuracy.

Improvements for Gear Grinding Accuracy

The machine bed design was developed with a central path for coolant and swarf removal. This symmetrical arrangement greatly reduces thermal effects, and the temperature compensation systems onboard compensate for any residual effects for ultimate accuracy over time.

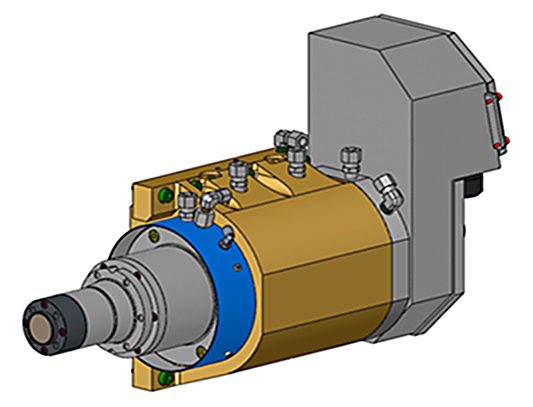

The grinding spindle on the hundreds of machines installed and operating provides excellent quality and meets all expectations of customers. As grinding wheel technology improves, new requirements demand improvements. The upgraded, highly rigid C version spindles are capable of 100 m/s grinding speeds and gear polishing (Figure 4). These spindles use an outboard bearing support for ultimate stability at high speeds and the challenging dynamic conditions during high speed generating grinding.

As EV and hybrid vehicle production increases, the need for quieter gears is greater. Improving the surface finish of gear teeth is often required, so the new MHI C version gear grinders offer polishing. Compound grinding wheels are used, having a portion with standard vitrified material, and a portion of a more compliant type of abrasive polishing material (Figure 5). The wheel is dressed as a standard wheel and is shifted to the polishing section after the conventional grinding cycle is complete. A significant improvement of the surface condition is possible with a Rz value of 0.4µ (micron) achievable (Figure 6).

Floor Space Reduction

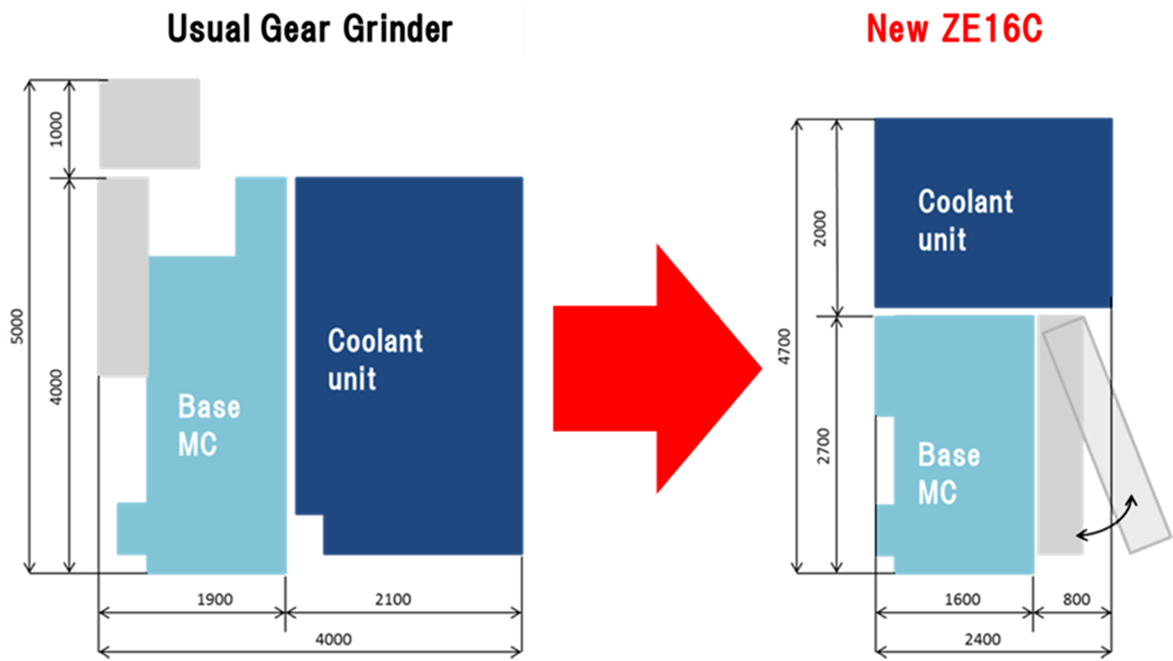

A common request from gear manufacturers is to reduce the floor space needed by gear grinders and especially the coolant systems. In responding to this, MHI designed the new ZE16C to take up only 55 percent of the previous machine, realizing a 45 percent reduction in the machine footprint. The width of the machine presented to the production line is on par with hobbing machines. By reducing the amount of coolant needed by the grinding process, and working with coolant system suppliers, the space required has been greatly reduced (Figure 7).

Ecological Friendliness

Most global companies are working to reduce their pollution footprint, and there are several reasons to reduce the use of oil in gear manufacturing where it is possible. MHI pioneered the world’s first dry hobbing in 1997 and has continued to pursue responsible innovations for environmental sustainability.

Together with a large automaker, a grinding wheel maker, and a coolant company, MHI co-developed both water soluble grinding technology and a coolant system for gear grinding (Figure 8). Not only does this reduce the slight risk of fire from oil use, but it reduces coolant cost by approximately 80 percent. An additional benefit is a threefold increase in diamond dresser life. This is in production and is highly successful. When oil is preferred by end users, MHI works with all coolant system manufacturers based on customer preference.

Small Changes = Big Improvement

The many small changes add up to a new state-of-the-art in gear grinding. With the emphasis on reliability and consistent productivity, the ZE16C and 26C represent the newest developments in gear grinding. By listening and working closely with customers using kaizen philosophy, MHI continues a tradition of innovation to deliver robust, productive and reliable gear manufacturing equipment.