Despite some 750,000 CNC mills put into service in the United States over the past 15 years, CNC machining job shops often hover at the bottom of the totem pole where there’s little room for error, as most bids are won by a 1-2 percent price variance. Representing the backbone of the U.S. machinery resurrection, most low-to-mid volume run production machine shops struggle in achieving their share of the 5-10 percent maximum profit margins typically realized on most jobs.

Given these constant challenges — along with changing consumer demands, overseas competition, a lack of skilled labor, and across-the-board changes in industry — the goal becomes how to improve efficiency, quality, and profitability in every business phase. CNC machining job shops are essentially multi-stage process operations where there is potential for improvement at each stage. Consequently, achieving a shop’s potential while expanding its business largely depends on how many of those improvements can be capitalized upon.

Ultimately, being better and faster keeps costs lower while raising the bar on potential profits. The ability to quickly adopt new machine tool technologies and cutting tool strategies becomes paramount to the overall success equation for today’s machining job shop sector.

Keeping a Competitive Edge

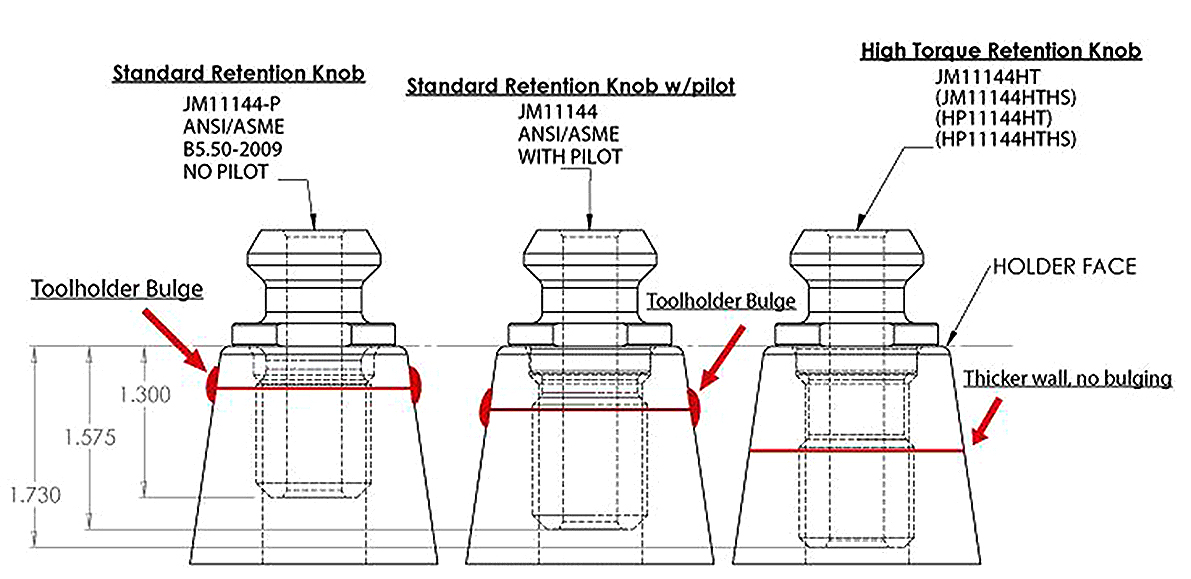

One of the quickest, simplest investments a job shop can make starts at the spindle with patented high torque retention knobs from JM Performance Products, Inc. (JMPP). The knobs overcome a key design flaw inherent in CNC v-flange tooling, eliminating the toolholder expansion responsible for costly and ongoing CNC milling and boring issues.

JMPP, a leading manufacturing innovator of CNC mill spindle optimization products since 2009, designed the knobs to be used in existing toolholders to eliminate the bulge at the small end of the holder, which stops it from making full contact with the taper of the spindle. By increasing contact with upwards of 70 percent more spindle surface, a wide range of CNC milling issues are overcome. They include vibration and chatter, poor tolerances, non-repeatability, poor finishes, shortened tool life, excessive spindle wear and tear, run-out, and shallow depths of cuts.

Since tight tolerances are essential in high-speed machining, if the toolholder doesn’t fit the spindle precisely, decreased productivity, and reduced tool life are inevitable. Bridging this gap of missed productivity can conservatively help job shop operations achieve a 10-20 percent competitive advantage per hour via faster set-ups, better feed rates, and more rigid tools, reducing tooling cost by 20-50 percent or more. In essence, every tool on the machine works better and faster to make job shops more competitive and increase profit margins dramatically.

The fact is, all U.S. manufacturers will have to bundle more technology in their products to compete, at home and globally. The power of combining lean manufacturing with modern technology is even more important to today’s small-to-medium job shop where everyone is competing for the same work. The positive short-and-long term effects of optimizing production methods with JMPP’s high torque retention knobs can help shops realize their full potential with a low-risk/high-return ROI ratio.

“A small advantage in labor hour savings alone can help impact a job shops’ leverage in getting the job,” said JMPP Plant Manager Craig Fischer. “With payroll hours reduced and machine hours freed up, the collective ability to get more work goes up. Additionally, everyone’s tooling budget keeps going up as the cost of buying carbide from China increases. Factoring in a conservative savings on carbide tooling costs of even 5 percent when using our knobs is significant, as all of these value-added factors collectively add up in a job shop winning more work in today’s competitive climate.”

Key design elements of these retention knobs include: longer than traditional retention knobs, with a precision pilot to increase rigidity; a relief below the flange forces threads into a deeper cross section of the toolholder; the knobs are hard turned to ensure precision fit, and are balanced by design with threads cut to start and finish 180 degrees from each other; and the high torque knobs will work in existing toolholders.

All JMPP retention knobs are manufactured and material sourced in the United States and made from hot rolled, 8620H or 9310H fine grain steel. H13 tool steel is also available upon request. They are shot peened to relieve stress, and hard turned for superior fit and finish. Only the high torque knobs are balanced by design. They meet all five world standards: ANSI, JMTBA, ISO or DIN, and JIS.

Application Profiles

Digital Machining Systems (DMS) of Lafayette, Louisiana: Founded in 1991, DMS is a custom machine shop that specializes in manufacturing small-to-medium sized precision CNC machined parts and assemblies. Expert parts manufacturers with some of the industry’s most technologically-advanced computerized machining equipment, DMS invested in two new machine tools from Milltronics USA in 2013 which required a knob style they didn’t previously have.

After investigating options, they decided to go with two machines worth of JMPP’s high torque style knobs, as they liked that the toolholder tapers and machine spindles would last longer and deliver overall better performance and part quality. They also felt like it was the right decision to make the switch to the high torque knobs, as it added to the constant improvement on the shop floor in overcoming ongoing production issues and they won’t buy anything else moving forward.

“We have been pleased with their performance as there have been no problems on these machines like fretting or tool taper damage,” said DMS Manufacturing Engineer Jeff Heels. “We also decided to start a replacement program for the worn-out knobs we used on our older Fadal CNC machine tools, and have been pleased with the performance there as well.”

Heels also noted another ancillary benefit about the knobs.

“The actual date of manufacture is printed on the knob,” he said. “This helps us keep track of how old the knobs are getting and will be helpful when it’s time to start replacing them again when they wear out. It also will help us gauge long-term performance data value moving forward.”

DMS Tooling Manager Eric Terradot has overseen their tool room since 2014 when they were already in the process of switching over to the high torque knobs for all of their machines. He handles loading the tooling that goes out to the machines, then unloading, inspecting, putting away tooling when the jobs are completed, and he also does the purchasing of the tooling.

“The quality and value for the price is excellent as we currently have well over 300 of JMPP’s knobs in service,” Terradot said. “We are also in the process of changing out our tool holders as one thing that is noticeable is we are not getting the markings and scuffing on the outer taper of the toolholders like we were getting.”

Enterprise Welding and Fabricating, Inc. of Mentor, Ohio: Founded in 1975, Enterprise is a family-owned metal fabricator specializing in sheet-metal fabrications with high-quality, cost-effective core component parts for large OEM companies with a heavy trucking and agricultural focus.

In 2017, Enterprise purchased two new DMG MORI machines (CMX 1100 & NHX 6300), which required a quick, full tool-up

conversion to JMPP high torque knobs — 30 for the CMX and 60 for the NHX. Notably, the NHX machine leveraged a higher strength version of the knobs since it was a bigger machine.

“We needed to get these machines up in one day, and JMPP came out and filled the order with our applications engineer onsite,” said Enterprise Manufacturing Engineer Bob Ludwig. “These were new machine investments, and the previous knobs and toolholders we used had bulged in the past, so we didn’t want to go down that path again. The assembly was simple, and we’ve used the knobs for over six months with high efficiency and no problems.”

Olson Custom Designs (OCD) of Pittsboro, Indiana: Established in 2014, OCD was founded by two brothers, Mitch and Brian Olson. With CNC machining being the backbone of OCD’s custom machining and fabrication operation, the family-owned job shop services a myriad of industrial markets including aerospace, medical, motorsports, agricultural, etc.

OCD owner Mitch Olson was seeking out the best tooling solutions to push their 2 mill, four- and five-axis milling machines to the limit. After some initial product demonstrations, Olson decided on JMPP’s high torque knobs and has not used anything else since.

“We’ve got the machines to handle nearly any material and run size, and any complexity so the job will be done right every time,” Olson said. “There’s a lot of money invested in the tooling and JMPP’s knobs provide better overall finishes, require less hours, and shorter runs for us as a job shop.”

part quality.

Conversion Productivity Index

The previous CNC machining job shop profiles are prime examples of conversion success on a variety of levels — spanning a myriad of diverse market applications including automotive, aerospace, medical, etc. Larger manufacturing entities have also been achieving similar results by adopting and implementing JMPP’s patented high torque retention knobs to meet and exceed the ever-changing requirements of CNC milling.

An increasing number of today’s job shops are performing machine tool monitoring in some way to analyze everything from managing tooling for jobs, scheduling jobs, configuring production, and daily rates. To aid job shop and manufacturing entities in identifying key cost analysis in converting to the high torque knobs, JMPP offers a free ROI calculator which can assist them in determining their annual projected savings. It starts with a simple equation — at a conservative minimum of 10 percent productivity increase using the high torque knobs vs. conventional knobs, how would it affect the health of your company?

Take the number of mills in your shop and multiply that times the number of hours per day you run. Now take that number and multiply it by the number of days per week that you’re running the mills. Multiply that number by your hourly billable rate. Now multiply that number by 52 weeks. The number you calculated is your unadjusted yearly revenue. Now, take that yearly revenue figure and multiply it by 10 percent — that’s the number that represents your annual lost revenue.

A simple example:

- 1 mill x 8 hours per day = 8 hours

- 8×5 days per week = 40 hours

- 40 hours x billable rate of $100=$4,000/per week

- $4,000 x 52 = $208,000 annually

- $208,000 x 0.10 = $20,800 lost revenue per year

Typical CNC milling centers are running machines 20-40 percent slower than they should be. A surge of CNC machining job shops and larger manufacturers are now recognizing that the high torque knobs are transforming v-flange tooling into the most cost effective, reliable, and precision tooling system available, improving finishes due to reduced chatter and vibration, and holding tighter tolerances.

About the author John Stoneback is president of JM Performance Products, Inc. based in Fairport Harbor, Ohio. For more information, go to www.jmperformanceproducts.com. JMPP 2018©, all rights reserved.